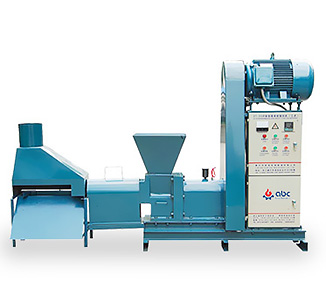

commercial pellet mill for industrial production

Commercial pellet mill refers to the pellet machine used for industrial pellet production. The commercial pellet mills for sale were used to make animal feed pellets in the past, but now they are more widely utilized in making biomass fuel pellets.

There are 2 kinds of commercial pellet mills: flat die pellet mill and ring die pellet mill. The flat die pellet mill came into being earlier than ring die pellet mill. Generally flat die pellet mill is suitable for small to medium scale industrial pellet production, while ring die pellet mill is suitable for large scale industrial pellet production.

Flat die commercial pellet mill

Working principle:when the roller rotate on the flat die, biomass raw material falls under the roller, and be pressed between the roller and die, then extruded from the die holes. Once the pellets go out from the die holes, the pellet cutter will cut them into set length. For the D-type pellet mill, the die rotates while the roller is stationary (only turns around vertically by the friction caused by moving raw material). For the R-type pellet mill, the die is stationary and the roller rotates horizontally and also vertically at the same time.

Flat die commercial pellet mill advantages:

- Flat die pellet mill is easier to clean than ring die pellet mill.

- The compact design, convenient operation and small capacity make it more suitable for small or medium scale biomass pellets production.

- The whole production process is visible, so that operators can find and correct the problems in time, such as why the pellets have poor quality, why the machine doesn’t work.

- It can process various kinds of raw materials, like wood materials or crop waste.

Disadvantages:

Its working principle determines its uneven abrasion of roller and die. Explanation: when the roller rotates, it has contact with the die plate, but the outer edge is much larger than inner edge, which makes the roller slide, and the slide can cause abrasion. So you should change the roller and die (together) once they have been used for some days.

GEMCO outstanding flat die pellet mill

As one of the world leading commercial pellet mill manufactures, GEMCO has improved flat die pellet mills manufacturing material and technology. Every piece of roller and die can be used to work at least 600-800hours, which is much longer than industry average.

Ring die commercial pellet mill

Working principle:Ring die pellet mill is composed by a ring die and inner roller. The raw material in the material storage hopper is fed into the center of pelletizing chamber by a screw feeder, and then pressed by the rotating roller to be extruded from the ring die holes, which is similar to a washing machine.

Ring die pellet mill advantages:

- It is more suitable for large scale industrial pellet production.

- Its roller and die are not easy to wear. The roller and die of ring die pellet mills are made from high chrome alloy, which is the most wear-resistant. Besides, high chrome alloy has higher degree of finish (than stainless steel or carbon steel alloy), which means they are easier to start, and has higher production efficiency. But they also cost higher than other materials.

- It has higher energy utilization rate.

Disadvantages of common ring die pellet mills:

- Its weight and size are much larger, therefore it requires larger worksop.

- When changing the roller and die, it requires more labor and time.

- The pelletizing process is invisible.

Nothing is perfect in the world, and commercial pellet mill is no exception. Through comparison, you will find GEMCO commercial pellet mill most cost-effective. Those who have purchased from us are quite satisfied with our commercial biomass pellet mills. A large proportion of them even become our regular customers or agents.

We believe good commercial pellet mill can speak for itself!