Why choose GEMCO Pellet Press

Pellet press is one kind of burgeoning energy efficiency machines in recent years. Its emergency owes to the worsening environment as well as human recognition of environmental protection. Nowadays, almost every part of the world has several sets of pellet presses o produce renewable energy source.There are countless biomass pellet press machine manufacturers all over the world, among whom GEMCO is a renowned one that can provide high quality pellet presses and also good price.

GEMCO pellet press (ring die) have the following advantages:

1.The ring die is made from 4Cr13 high-chrome alloy and processed by high temperature vacuum quenching. This kind of material has longer service life than carbon steel alloy, and has higher hardness.

This kind of material has longer service life than carbon steel alloy, and has higher hardness.2.The forged synthesis GEMCO pellet making machine main shaft.

The contact surface of main shaft and roller seat is large, which makes both sides of the shaft have balanced stress and assures the lowest damage to accessories.

3.The disassembling and installing device of the pellet making machine rollers has compact structure but is stable and durable to use.

It can satisfy the disassembling and installing requirements of the roller bearing, make the process easier, faster and more efficient. The lifting-jack also makes sure accuracy and no off-axis for the bearing.

4.The German FAG imported bearings and oil seal provide higher efficiency for the pellet making machine.

5.The double ring die connected by interference.

This innovation can greatly enhance the fatigue strength of ring die when making wood pellets or under other heavy load conditions, keeping the ring die away from cracking.

6.Advanced air cooling and dedusting system.

The national patented pellet making machine adopts air cooling system that uses flowing air to cool the pelleting chamber and realize cold pressing. The system also can remove the dust and impurities from the biomass, at the same time collecting the powder raw material for reproduction. This not only lengthens the pellet making machine lifespan, but also increases productivity, which is a significant innovation is pellet making industry.

7.The pellet press main shaft adopts oil adding device.

Taking the advantage of the flowing nature of oil, this new type lubrication device can deliver the oil to the main shaft oil filter pipe smoothly and fast without polluting the engine oil inside the pellet making machine main body. This device also makes the bearing balls fully contact with the oil, improving the lubrication condition.

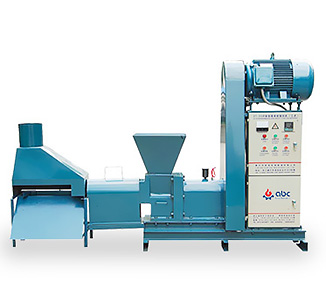

GEMCO Ring Die Pellet Press

There is a material sweeping device in the storage bin. Driven by the electric motor, the blades of the sweeping device turn around, and push the raw material into the discharging hole. As a result, the raw material will not block the pellet making machine holes.

GEMCO pellet press machines with large capacity have been exported to many countries and areas all over the world to serve their local markets. And a large proportion of investors have made great profit; others just set up their pellet plants and will make profit in the near future.

Are you also interested in GEMCO pellet making machine? Feel free to contact us! Small pellet press click here: http://www.gemco-machine.com/pellet-mill-for-home-use.html

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!